Steelanol

Fueling a sustainable future

Get to know more about Steelanol

ArcelorMittal, the world’s leading integrated steel and mining company, has started the construction of a groundbreaking bioethanol facility at the Ghent site. Via the Steelanol plant ArcelorMittal will transform part of the carbon-containing exhaust gases from our two blast furnaces into advanced bioethanol, to be used as sustainable fuel for transportation or even as raw material for the production of synthetic materials. The Steelanol plant aims to demonstrate the possibility to produce biofuels at industrial scale through an innovative gas fermentation process using bacteria to capture the carbon-rich gases emitted by our steelmaking activities and convert these in bioethanol. Steelanol will be the first industrial installation of its kind in Europe, and the largest facility built to date utilizing this technology globally, producing 80 million liters of bioethanol annually starting from 2023.

A-leaf

A photo-electro-catalytic cell from earth-abundant materials for sustainable solar production of CO2-based chemicals and fuels

Get to know more about A-leaf

Overarching goal: Transformation of carbon dioxide into a renewable fuel with sunlight

Technology class: (Photo)electrochemical

Feedstock: CO2 and H2O

Product(s):HCOOH, H2 and O2

Sustainability criteria: NO critical raw materials;

Novelty/Unique Selling point: Record solar to CO2-based fuels productivity with a technology based on non-critical raw materials.

Bottlenecks tackled: Matching the features of light absorbers, cathode and anode to work together at maximum performance point.

Starting TRL: 2 / End TRL: 4

Timeline:2017-2021

Funding type received: H2020 FETPROACT-2016 RIA (grant agreement 732840)

ReuZe

A solution for the hard to abate transport sector

Get to know more about ReuZe

Overarching goal: Providing a solution for sectors that can’t decarbonize on the short & medium term. Technology class: Electrochemical conversion. Feedstock: Water, CO2 and electricity. Product(s): SAF (eKerosene), eDiesel, eNaphta, oxygen, heat (all products are carbon neutral). Sustainability criteria: waste or salinated water use.

Novelty/Unique Selling point: – Size (incl. technology & integration), – Re-use of existing infrastructure & molecules, – New business model,

Benchmark to existing approaches: – Economies of scale, – Unlimited feedstock (if electricity is available), – Easy expedition of end products, – Move fast

Bottlenecks tackled: – Electrical connection, – Availability of renewable assets, – Alignment with EU regulation (delegated acts), – Price electricity

Starting TRL: 7&8 /

End TRL: 8&9

Timeline: COD in 2027

Funding type received: France – ADEME

Hanu Ori

Contact: Prof. Max Fleischer (Siemens Energy)

Get to know more about Hanu Ori

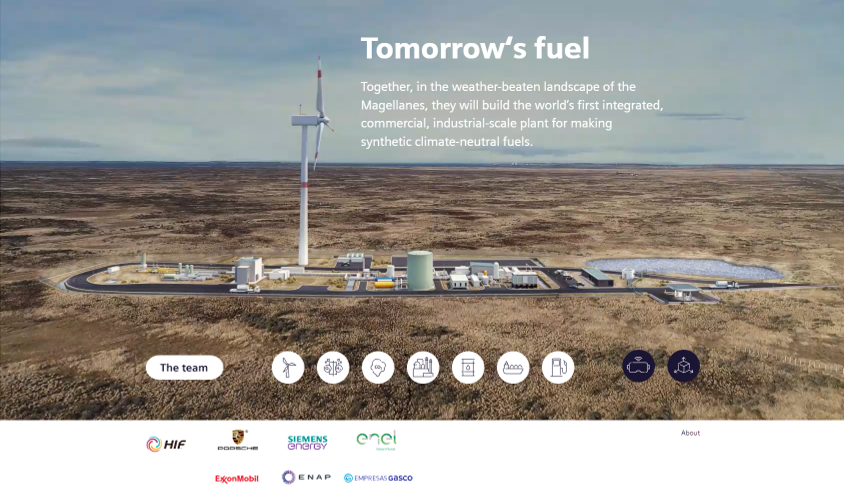

Together, in the weather-beaten landscape of the Magellanes, they will build the world’s first integrated, commercial, industrial-scale plant for making synthetic climate-neutral fuels. Technological details: • Siemens Gamesa wind turbine SG 3.4 132 with 3.4 MW, then expanded to around 280 MW, industrial scale 2.5 GW. • Silyzer PEM technology from Siemens Energy to convert wind energy to green hydrogen • Start with Global Thermostats (GT) direct air capture equipment to harvest CO ₂ • MAN supplying the methanol synthesis reactor based on Johnson Matthey’s design. • Fluidized bed MTG (Methanol To Gasoline) technology to convert green methanol to synthetic gasoline, licensed and supported by ExxonMobil. Video on: https://www.siemens energy.com/global/en/news/magazine/2021/haru oni.html

Green hydrogen to Sustainable Aviation Fuel demonstrator plant

Get to know more about the project

Overarching goal: Establish a demonstrator plant at Masdar city to explore the development of e-jet and and its use by major commercial airlines.

Technology class: Multiple

Feedstock: CO2, H2O

Product(s): e-jet

Novelty/Unique Selling point: One of the first demonstrator plants for e-jet production and its use by major commercial airlines.

Benchmark to existing approaches: No existing pathways.

What is the anticipated breakthrough? Identify & demonstrate viable pathway for e-jet production.

End TRL: First operational project in industrial environment (TRL 7).

LICROX

Light assisted solar fuel production by artificial CO2 Reduction and water Oxidation

Get to know more about LICROX

Overarching goal:

In LICROX we will fabricate and test a photoelectrochemical cell (PEC), an artificial photosynthesis device, for converting sunlight, water and carbon dioxide (CO2) into carbon-based molecules.

Technology class: Photo(electro)chemical

Feedstock: sunlight, water and carbon dioxide

Product(s): main target is ethylene

Sustainability criteria: Use of critical raw materials: no; waste or salinated water use: no

Novelty/Unique Selling point:

Use of non-noble metal catalysts, tandem structure consisting of a photoanode, a semi-transparent organic solar cell, and a photocathode

Bottlenecks tackled: Broadband absorption of sunlight to achieve high current densities for an efficient conversion of carbon dioxide (CO2) into carbon-based molecules containing 1 carbon (C1) or 2 carbons (C2), capable of storing chemical energy

Starting TRL: 2/End TRL: 4

Timeline: 3 years (September 2020-August 2023)

Funding type received: This project has received funding from the European Union’s Horizon 2020 research and innovation Programme under the grant agreement No. 951843.

Sofia

Soap Film based Artificial Photosynthesis

Get to know more about Sofia

Overarching goal: We have a potentially scalable device solution for production of Solar Fuels and industry feedstock (Green H2, Carbon based fuels from CO2 and water) using Artificial Photosynthesis.

Technology class: Photo(electro)chemical

Feedstock: CO2, Water.

Product(s): Green H2, CO.

Sustainability criteria: No use of critical raw materials

Novelty/Unique Selling point: We use Soap Bubbles as photocatalytic reactors. They can be easily and economically generated and scaled.

Bottlenecks tackled: We have synthesized surfactant (soap) grade molecular photocatalysts. We have validated our concept design by demonstrating stable dissymmetric soap film membrane. We are in the process of optimizing and fabricating our designed proof of concept design

Starting TRL: 1 / End TRL: 4

Timeline: Project Start- 1st January 2019. Project End- 30th June 2023.

Funding type received: H2020 FET Open. EU contribution € 3 205 280. Grant Agreement No. 828838

IMPOWER2X

Get to know more about IMPOWER2X

Overarching goal: Providing sustainable, CO2 neutral & affordable e-fuels & e-products for everyone

Technology class: Electrochemical conversion

Feedstock: green H2 / CO2 (industrial/biogenic source and/or Direct Air Capture

Product(s): Synthetic fuels: FT-crude / FT-Diesel / FT-Wax

Sustainability criteria: Use of desalinated water and exclusively green hydrogen from renewable energy

Novelty/Unique Selling point: We prioritize a numbering-up strategy to scale-up our technology and support the serial production to allow the quick ramp-up of affordable sustainable e-fuels for the aviation, shipping and automotive sectors.

Starting TRL: 6 / End TRL: 8

Timeline: 2 years (May 2021-April 2023)

Funding type received: EIC Accelerator (H2020, Grant Agreement No. 970564)

FuturoLEAF

Leaf-inspired nanocellulose frameworks for next generation photosynthetic cell-factories

https://futuroleaf.com/

Get to know more about FuturoLEAF

Overarching goal: We develop a nanocellulose-based solid-state photosynthetic bioproduction platform for efficient biological carbon capture and sustainable production of chemicals.

Technology class: Solar energy conversion using biological components and biobased materials

Feedstock: Photosynthetic cells and nanocellulose

Product(s): monomers, hydrogen, ethylene, active pharmaceutical ingredients

Sustainability criteria: Use of renewable sources without interfering food supplies, biobased materials and biotechnological pathways, reduced water and energy consumption with increased chemicals production efficiency

Novelty/Unique Selling point: We use several inherent features of nanocellulose-based immobilisation matrix to improve cell viability, cell lifetime and their production efficiency.

Bottlenecks tackled: Improved mechanical stability of matrix also in challenging production conditions, water intensity as compared to suspension cultures reduced, restricted cell growth directs the energy towards targeted chemicals production

Starting TRL: 1 / End TRL: 3

Timeline: 1.9.2020 – 31.8.2023

Funding type received: Funded by the Horizon 2020 Framework Programme of the European Union funding for Research and Innovation (RIA) – Future and Emerging Technologies FET. Grant Agreement No. 899576

SunCoChem

Carbon-neutral production of energy and high-value chemicals

https://suncochem.eu/

Get to know more about SunCoChem

Overarching goal : The EU-funded SunCoChem project will produce a competitive and integrated solution to reduce the industrial CO2 emissions to the atmosphere by developing a tandem and self-biased photoelectrocatalytic reactor that will use just sunlight, water and CO2 to produce high-value chemicals.

Technology class: Photo(electro)chemical CO2 conversion.

Feedstock: CO2, industrial wastewater (with olefins)

Product(s): oxo-products (i.e. glycolic acid – a polymer building block, valeraldehyde – a flavour ingredient, and LimoxalTM – a fragrance ingredient).

Sustainability criteria: low use of critical raw materials; use of wastewater.

Novelty/Unique Selling point: Novel concept of compact and easily scalable TPER device design to be used as artificial leaf, including: – ANODIC CHAMBER with Smart photoelectrodes for Water oxidation to O2; – CATHODIC CHAMBER with Photo- and non-photoassisted coupled reactions: Selective PEC CO2 reduction to CO; CO-hydroformylation of OXO-products. High CO2 conversion via Ionic Liquids electrolytes. Stable & efficient MEA via a transparent bipolar membrane; – Integrated FLUE GAS Cleaning & CO2 CAPTURE CHAMBER: CO2 capture from flue gas stream with asymmetric polysulfone membrane and CO2 concentration in Ionic Liquids; – Use of low-cost PEROVSKITE SOLAR CELLS to boost internal photo-voltage

Bottlenecks tackled: Efficiency: > 10% of Sunlight to CO conversion efficiency & current density of 20 mA·cm2; Stability: < 5% of performance loss in 1000h of operation; Sustainability: < 50% CO2 emissions versus actual routes for oxo-products production from fossil fuels.

Starting TRL: 3 / End TRL: 5

Timeline: 48 months (2020 – 2024)

Funding type received: EU H2020 – INDUSTRIAL LEADERSHIP – Leadership in enabling and industrial technologies – Advanced materials. Grant Agreement No. 862192